Services

We offer high quality products – and even more

This is how your Three-Tec device is created

Each of our customers has very specific requirements. Thanks to the in-house development and manufacture of our products, we can implement special solutions flexibly and promptly in cooperation with you, while ensuring the highest quality standards.

1. Your requirements

You tell us your requirements, we advise you individually and together we find the right solution.

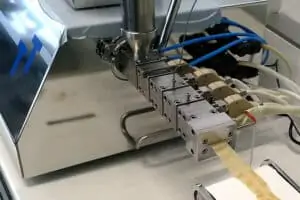

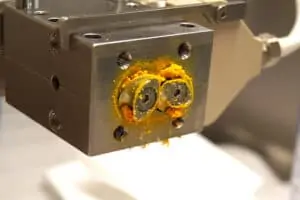

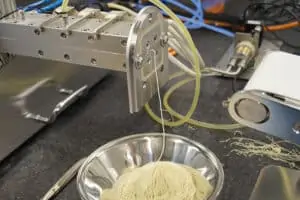

2. Tests

Together, we conduct tests in our test lab with your original products to accurately define the device.

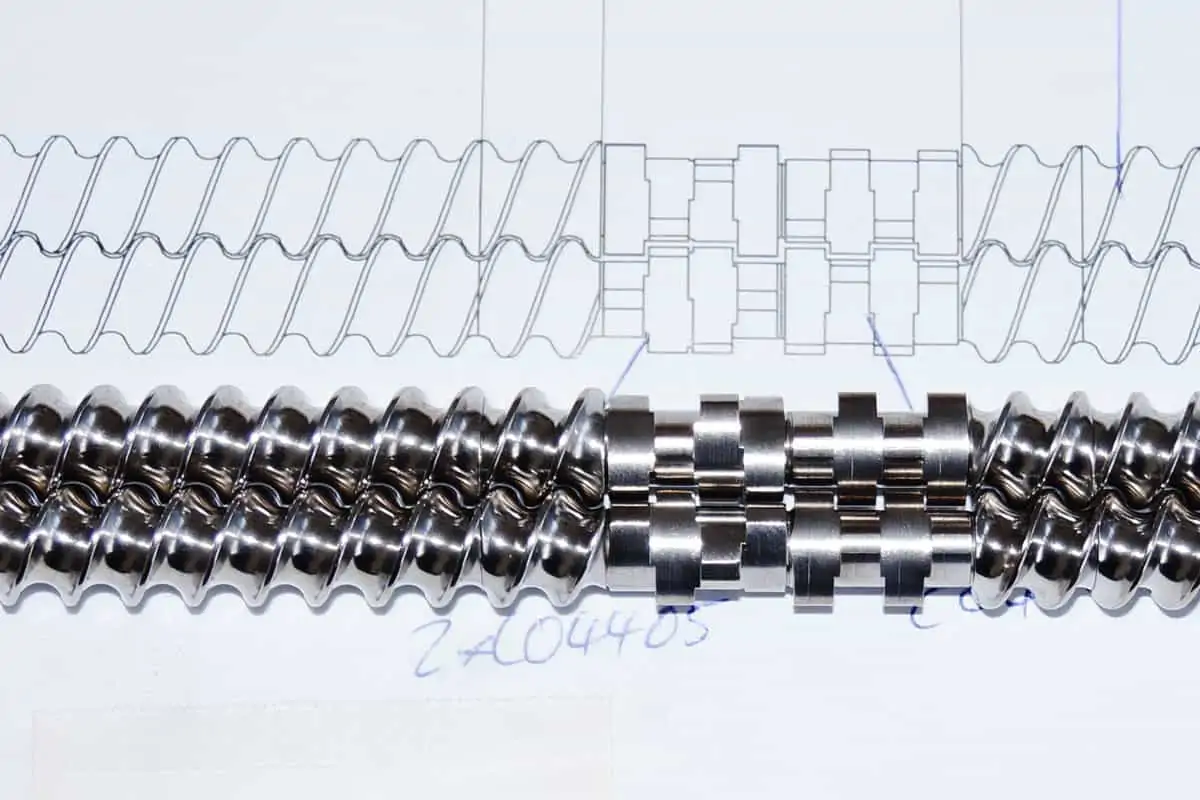

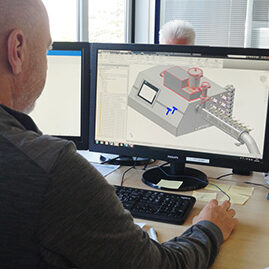

3. Development

Our specialists develop the feeding device or extruder according to your requirements using Autodesk Inventor 3D and create a acceptance drawing.

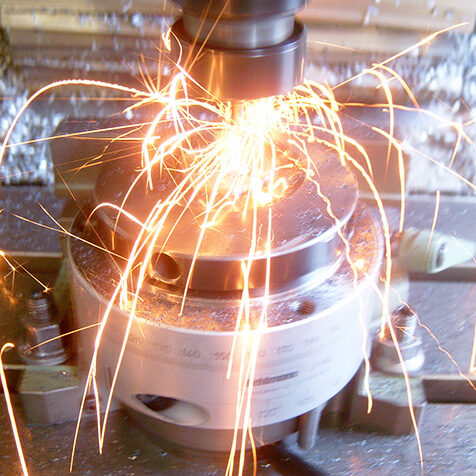

4. Manufacturing & assembly

In our workshop all parts are made of high quality materials and are assembled by specialists.

5. Control system

The careful construction of the control system is carried out in-house, as is the individual programming.

6. Commissioning

The commissioning of the device is carried out either at our premises or at the customer's site, depending on the customer's wishes.

7. Documentation

You will receive detailed documentation from us for your device according to your requirements.

8. Spare parts & maintenance

We guarantee the availability of spare parts for at least 10 years from purchase and service your device worldwide.

Service & Maintenance

In addition to products with the highest quality standards, we offer a wide range of additional services.

Trainings & Workshops

Practical applications of our devices and compact theory units: In our workshops, you will receive the necessary basic knowledge on how to use the devices optimally. In addition, customer-specific tasks are worked on and individual needs are addressed.

We organize regular seminars and workshops on the following topics:

Currently there are no training dates planned. Are you interested in training courses and workshops? Then get in touch with us via the contact form. As soon as the next date is known, we will contact you.