Special machinery

Isolator High Containment, filling systems and more

Isolator High Containment

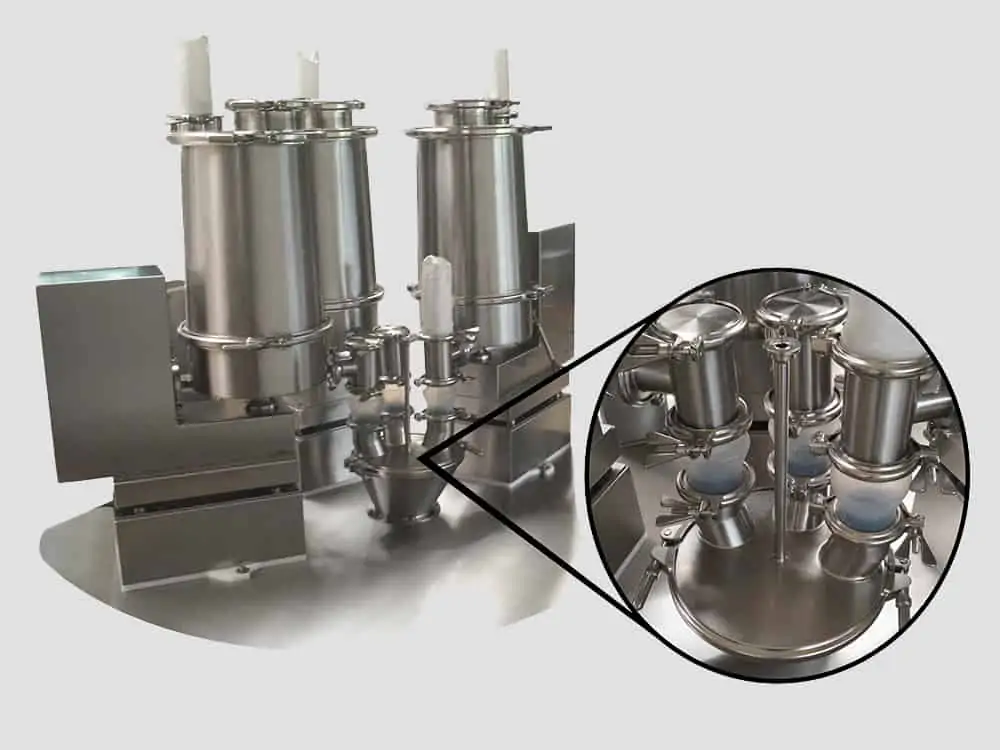

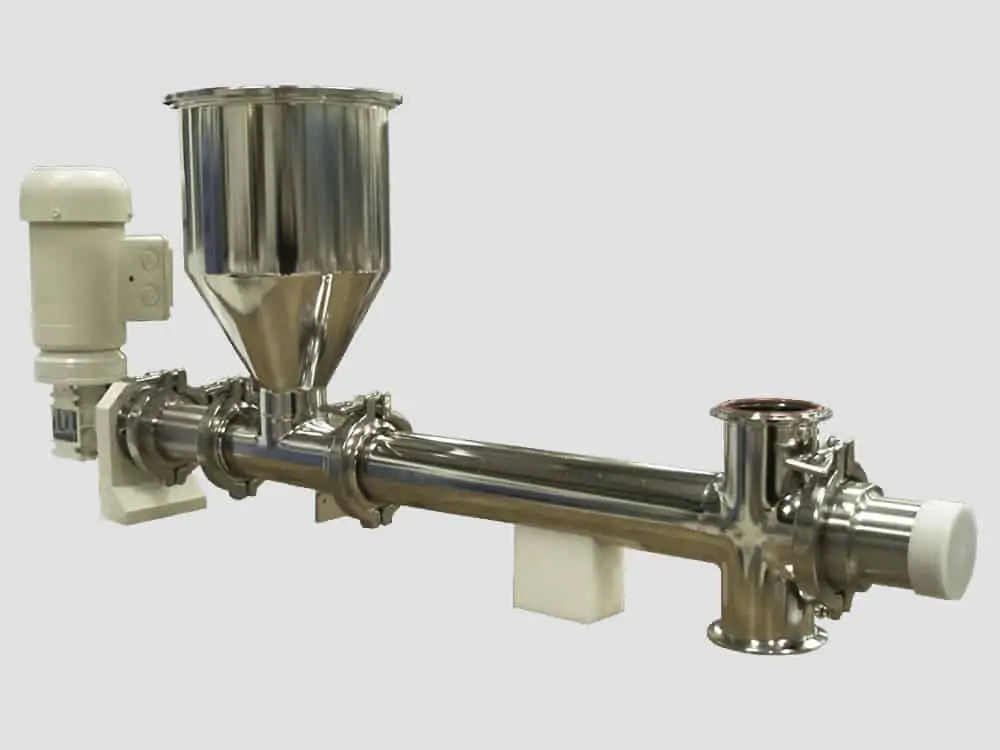

A complete production line in high containment according to ISO 14644-7: a feeder, an extruder, a conveyor belt with cooling and a pelletizer are integrated in the isolator. This means that the process from powder mixing to the finished granulate takes place in a protected and controlled environment, which eliminates the need to set up a complete clean room. The equipment can also all be removed individually from the isolator. This frees up space for other machines or applications as needed. The isolator thus becomes a multi-purpose device.

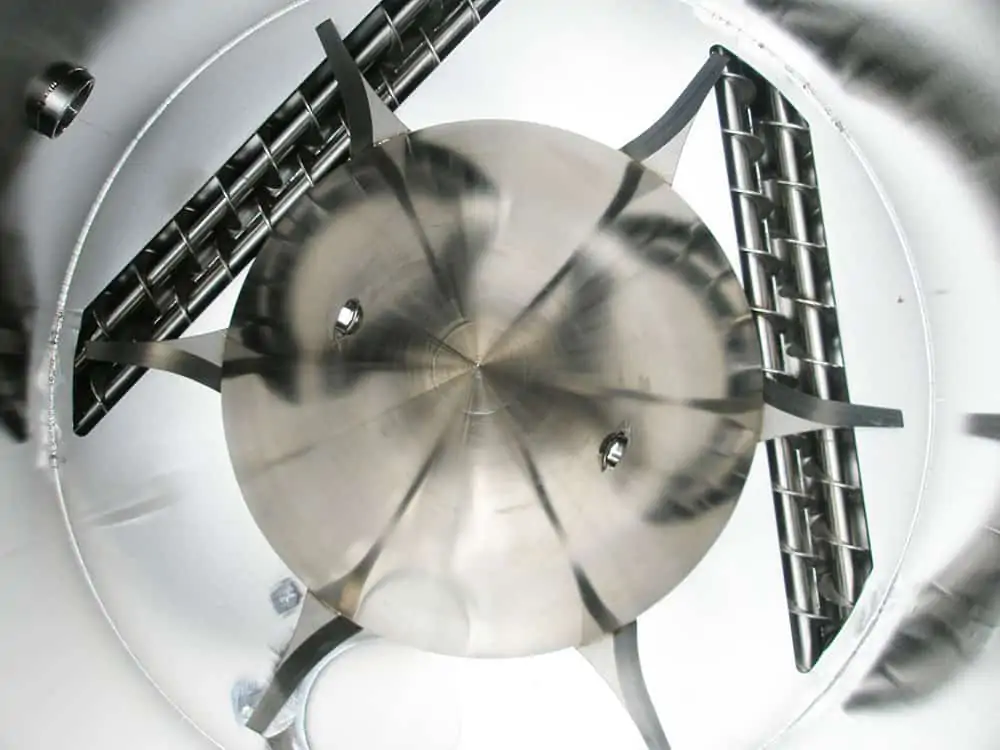

The built-in machines are specially designed for handling with gloves and can be easily disassembled and cleaned by an operator. The working chamber as well as all product-contacting parts of the machines integrated in the isolator are made of stainless steel 1.4404 (316 L) with a surface finish of Ra ≤ 0.8 µm.

The controlled and filtered supply and exhaust air creates a controlled negative pressure with compliance with cleanliness class C (OEB 4/5) in accordance with GMP guidelines and guarantees that no product can escape to the outside (inflow) even if a glove is torn off. The fail-safe components, the automatic pressure retention test and the static front panel seal made of EPDM also ensure the safety of the operator and his environment. All filters and gloves can be replaced without contamination.

The filling of the gravimetric feeding system in the isolator and the discharge of the finished granules take place via interlock sluices, double door locks or double flap locks (RTP port).

The entire system can be optionally equipped with gas/compressed air extraction points, cleaning guns/WIP dies, vacuum cleaning system and inerting, and is also built as an explosion-proof and antistatic version.

The drives of the machines are deliberately housed outside the isolator via flanges. The complete production line is operated via a central Siemens TP 1200 Comfort Panel.

Application areas

- Food

- Pharma

- Laboratory

- Up-Scale

- Research & Development

Contact

Do you have any questions or would you like personal advice on our special machinery?

Other special machinery

Other special machinery is developed and produced upon customer request. Some examples of special machinery that Three-Tec has produced: