Every feeding and extrusion task is unique. That is why Three-Tec does not produce standard solutions, but adapts each product exactly to the application. This is made possible by the development and manufacture of all devices at our own site in Seon AG, Switzerland.

Large series with standard solutions are a foreign word for Three-Tec. Each customer and each order have their specific requirements, which must already be taken into account in the development of the equipment. The best feeding and extrusion results can only be achieved with devices and equipment that are optimally matched to the process and have the required quality level. Therefore, almost only custom-made products leave our premises. In our own workshop, our specialists exclusively manufacture workpieces for our own products. Our own development and production not only guarantee the highest quality standards and the greatest possible flexibility, with which we can respond to the wishes of our customers, they also enable complete traceability and control of all processes.

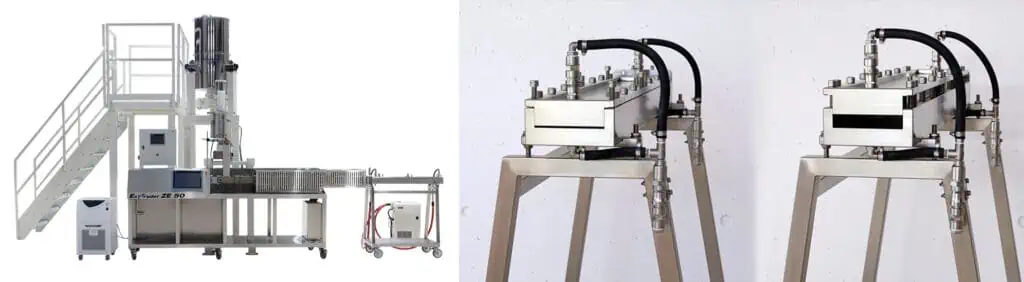

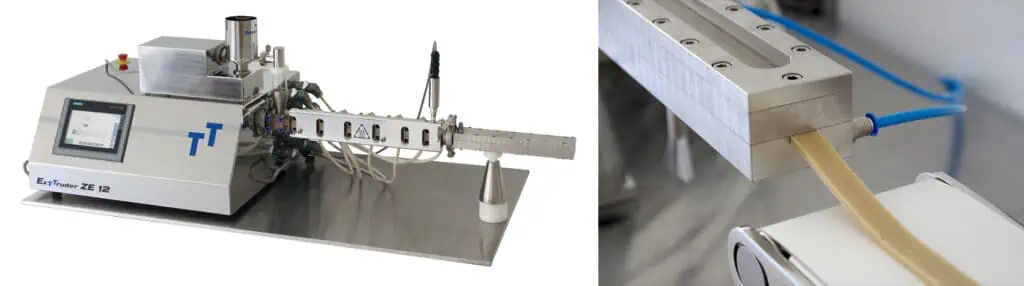

For over two decades, Three-Tec has been successfully operating internationally, serving customers from all demanding industries in 40 countries. Thanks to its many years of experience, Three-Tec finds a suitable solution for every requirement. As one of the few suppliers, Three-Tec offers, for example, extruders in miniature scale from a size of 5 mm screw diameter, with which even the smallest quantities from one gram can be processed. In addition, the Hybrid laboratory extruder is an innovative solution that allows two extruder sizes to be covered in one unit (two selectable screw diameters of 5, 9 or 12 mm). Among other things, this enables resource-saving formulation development in the pharmaceutical sector with very valuable active ingredients and subsequent scale-up of the process.

To ensure that you get the perfect product for your needs, we offer our customers everything from a single source: from feasibility tests in our test lab to development, manufacturing and programming to service and support. In our in-house test lab, we offer our customers the perfect environment to test equipment with original products and determine exactly the right setting to achieve the best results. Thanks to our satisfied customers, who support us with their feedback and recommend us to others, Three-Tec has been able to grow continuously over the past years and now employs around 40 people.

Do you also have a feeding or extrusion task for which we can support you? Then we look forward to hearing from you.