While meat consumption per capita is declining, the market for meat substitutes is growing steadily. Extruders are an important element in the production of meat analogues. At its own site, Three-Tec produces high-quality extruders, which are also increasingly used for the production of meat substitutes.

Meat substitutes are generally more environmentally friendly than conventional meat and consume significantly fewer resources in production. With the trend towards more conscious meat consumption or complete renunciation, the demand for meat substitute products is also increasing. Extruders play an important role in the production of individual meat substitute products. Processing in an extruder gives vegetable proteins such as pea, soy, wheat proteins, etc. the desired meat-like texture.

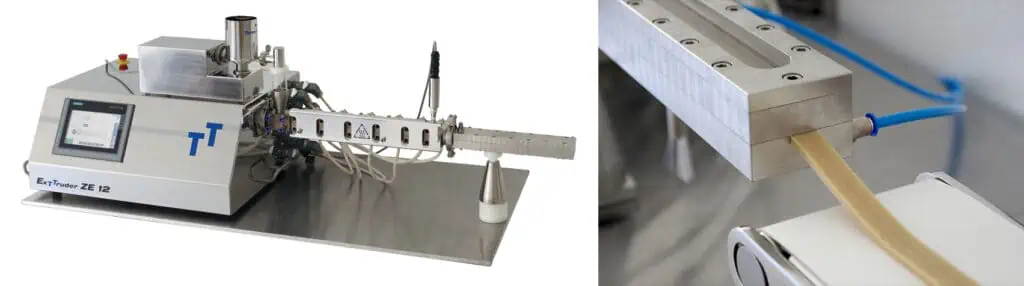

Three-Tec offers twin screw extruders (co-rotating) whose end products meet the increasing demands of customers and the industry. With the in-house flat-tray feeders, even very poorly flowing powders can be precisely fed, which forms the basis for a stable extrusion process. Subsequently, the protein-containing product is mixed with water, kneaded, cooked and expanded as textured vegetable protein (TVP) or textured as a meat substitute product with a high water content (HMMA) by means of a cooling die and shaped into the desired form.

Three-Tec's extruders are excellent for the production of small quantities for applications in research and development as well as for production quantities. They are equipped with easily exchangeable extrusion dies, which can be individually set up and adapted to the extrusion task by means of different segments such as conveying, return conveying, kneading or mixing segments. The temperature profiles of the individual heating zones and the torque of the motor are recorded and can be read out via USB or Ethernet interface.

Thanks to the in-house development and production of our products, we can offer customized solutions with the highest quality standards and the greatest possible flexibility. Almost only custom-made products leave our premises, developed and produced exactly according to the customer's requirements.

You can find more information about Food Extrusion here. Are you looking for high-quality equipment for the production of meat substitute products? Then we look forward to hearing from you.